Built with purpose, the TL5500 easily switches from round to square bales with a few quick adjustments. Raise the two table rails to give the bale proper clearance and raise the roller bed to ensure the proper discharge angle.

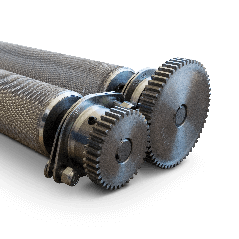

To create the 55% (approx.) stretch of the plastic, the pre-tensioners are knurled which allows them to grip and pull the plastic between the rollers activating the bonding agent in the film.

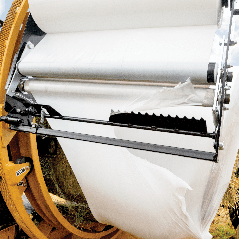

Standard on all inline Balewrapper models, Tubeline’s Film Snap easily cuts wrap with a single action. Press and hold the Film Snap plunger located beside the operator’s panel until both the tensioners pass, triggering the cutting action. The Film Snap bar snaps into action safely cutting the wrap without stopping the cycle.

Inline wrappers carry a 3 Year Limited Warranty. For more information please contact Tubeline Manufacturing.

| Specifications | TL 5500 AX2 | TL 5500 ECV |

|---|---|---|

| Overall Length | 25' 6" | 25' 6" |

| Width | 9' | 9' |

| Height | 9' | 9' |

| Weight | 5,800 lbs. | 5,800 lbs. |

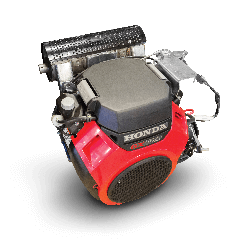

| Power | 13 Hp Honda | 13 Hp Honda |

| Electric Start | Standard | Standard |

| Alternator | 18 Amp. | 18 Amp. |

| Hydraulics | Self-contained | Self-contained |

| Controls | Electric over Hydraulic | Electric over Hydraulic |

| Tires | (4) 11L x 15 8 Ply | (4) 11L x 15 8 Ply |

| Tires with Power Drive | (2) 11L x 15 8 Ply (2) 27 x 10.5 Traction |

(2) 11L x 15 8 Ply (2) 27 x 10.5 Traction |

| Quick Start Leveling | Hyd. Lift Jack (Opt.) | Hyd. Lift Jack (Opt.) |

| Brakes (Compactor) | Adjustable Cam Action | Adjustable Cam Action |

| Steering | Electric over Hydraulic | Electric over Hydraulic |

| Emergency Stop | E Stop Button | E Stop Button |

| Hydraulic Tail Gate | Standard | Standard |

| Transport Lights | Standard | Standard |

| Bale | ||

| Round | Up to 5' 6" | Up to 5' 6" |

| Square (Single) | Up to 3' x 3' x 5' 6" | Up to 3' x 3' x 5' 6" |

| Square (Double Stacked) | NA | NA |

| Film Stretcher | (2) 30" x 55% | (2) 30" x 55% |

| Bale Alignment | Adjustable | Adjustable |

| Bale Guide Rollers | Optional | Optional |

| Hoop Speed | Adj. Flow Control Valve | Adj. Flow Control Valve |

| Cycle Times* | ||

| 5' Round (66" Cycle Length) | 29 sec. | 29 sec. |

| 4' Round (54" Cycle Length) | 23 sec. | 23 sec. |

* NOTE: BaleWrappers applying 8 layers - equipped with 20HP Engine, High flow pump, and Twin Wrap Kit.

Honda Engines power the fluid through the hydraulic system ensuring efficient flow from the reservoir to valve body. The 20HP engine comes with a high flow pump providing an ample supply of fluid to the valve body.

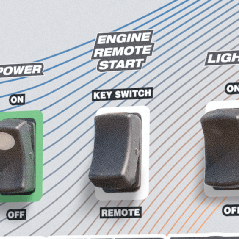

This rugged remote allows you to start, shut down, and control your wrapper remotely.

This switch, located on the control panel, toggles between the engine starting with the key directly, or by using the remote.

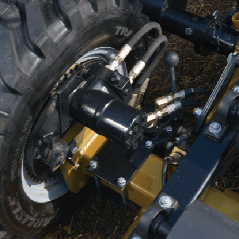

Both the single and dual hydraulic power drives give your wrapper's drive system more power to get through tough to drive through areas.

The guides rollers are located on the tail of the wrapper to help guide the bales after being wrapped, reducing risk of damage.

The night working light kit extends your working hours to ensure you get all your wrapping done no matter when you start.

The night working light kit extends your working hours to ensure you get all your wrapping done no matter when you start.

A level roller bed secures the first bale for a tightly packed start to your row.

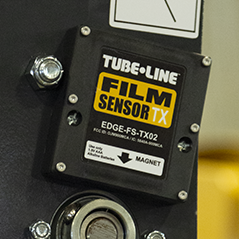

The film sensor automatically shuts down the wrapper hoop when it detects a break in the film, or when the wrapper runs out of wrap.

Using wireless technology, Tubeline’s Film Sensor TX can detect when your wrap breaks or runs out and automatically sends a shut-down signal to the machine. This ensures your bales don’t go through the hoop without proper coverage.

Tubeline's Twin Wrap Kit holds two rolls of film and passes them through a single stretcher. This activates the wraps' bonding compound to form a strong 2-Ply layer of film that stands up to tough hay stalks and folds them over helping to prevent piercing of the wrap.

By combining two sets of two rolls for a total of four, Tubeline's twin wrap kit provides all the same protection as four separate stretchers with the additional benefit of producing a more durable bonded 2-Ply film that stands up better than four single ply layers.

Tubeline’s new laser guided steering system makes small incremental adjustments to keep the wrapper tracking along the desired path. The laser constantly takes measurements and automatically makes steering adjustments to maintain the programed distance from another bale tube, fence line or even dense crops.

Errors and omissions excepted. Specifications and images on this page are subject to change without notice. For current information on all of our products, please contact Tubeline Manufacturing.